For some people, CNC programming is a quite technical and complex term. The truth is that it makes the modern manufacturing system easy making it a highly essential part of the process.

CNC, or Computer Numeric Control, was already used in the mid-19th century by the military forces of the United States. The use of CNC is not as complicated as it may seem. They have used Cartesian coordinates as a method of instructing the machine to operate. The coordinates X 1, Y -3 comes with commands such as ‘start spindle’ so that the operators can use this program in CNC machine automation.

1. The Essence of CNC Programming

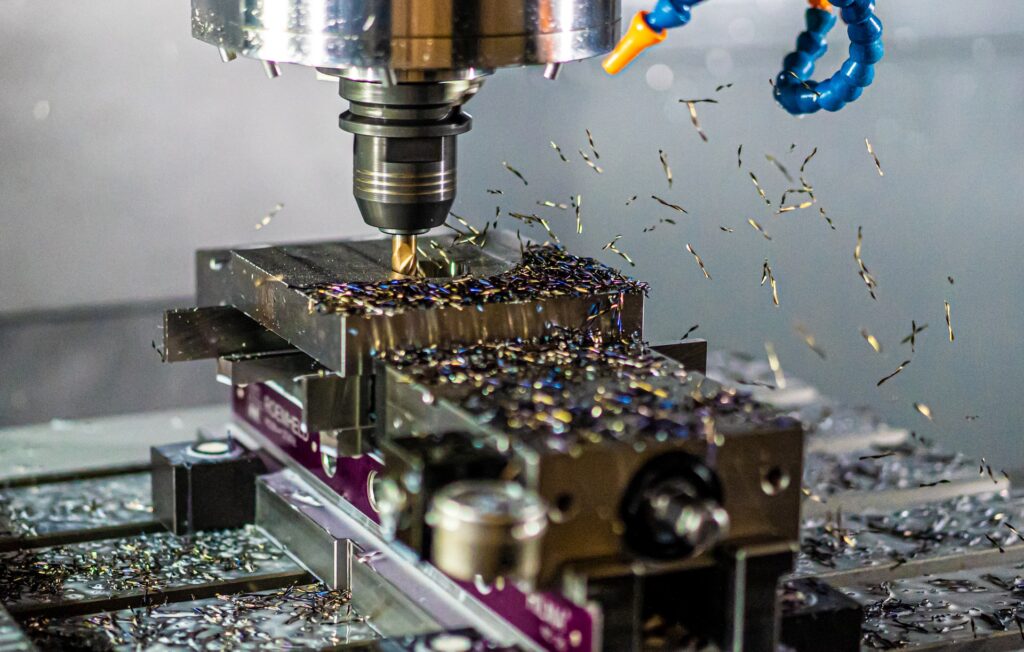

Using Computer Numeric Control, it is more obtainable to automate any CNC-equipped machine. The CNC operator does not have to control every step of the process. Rather, he is responsible for starting the program and commanding the machine. It is the CNC programmers that need to be trained to be able to work in research facilities, manufacturing businesses, repair shops, and more.

2. What is the G-Code?

CNC helps operators to command machine equipment using coordinates to program instructions. However, there are more aspects involved than the basic coordinate pair series. There is a specific programming language used for these CNC tools which is called G-Code. So, what is G-Code and how does it work in the manufacturing processes? How does it benefit the business in terms of production? Here are the answers you need to know about this programming language.

Operators need to understand all jargon in the world of CNC automation. Another term that they will need to learn about is the G-code. This term is derived from the way the codes are named such as “G01”. Then, it will be followed by X and Y coordinates which command the machine tools what to do.

The programmers use codes for different areas of CNC automation – movement speed, spindle speed, switch tool commands, etc. For instance, operators should learn about CNC lathe as well. It should be able to figure out what to do for the whole duration. Some of the commands are about what and where to cut the material or how fast it should move along the part. Now, this is where the G-code comes as the operator should enter a line of code to automate the machine.

A safety block starts with G-code programs and they work to set limitations, to function as defaults, and to reduce the chances of errors in the program.

An example of a safety block is “G20 G90 G54 D200 G40”. This is a series of specifying tool offsets, measurement units, and settings that are needed in the entire program.

G-code can also use shortcuts in the form of simple codes representing a series of actions when possible. One of the most common examples is the code G26. This number means a ‘return to home position’ command, instead of entering the exact coordinates. The operator does not have to do a lot of manual tasks to set up the machine and work efficiently. As long as he knows how the G-codes work and what each code means, it will be easier to enter the command of the CNC programs.

3. A Short Glimpse of CNC Applications

Many large companies today use CNC automation to maximize their productions and limit time and man force in each process. With computer numerical control, every program can be saved and repeat in the next manufacturing process even a thousand times.

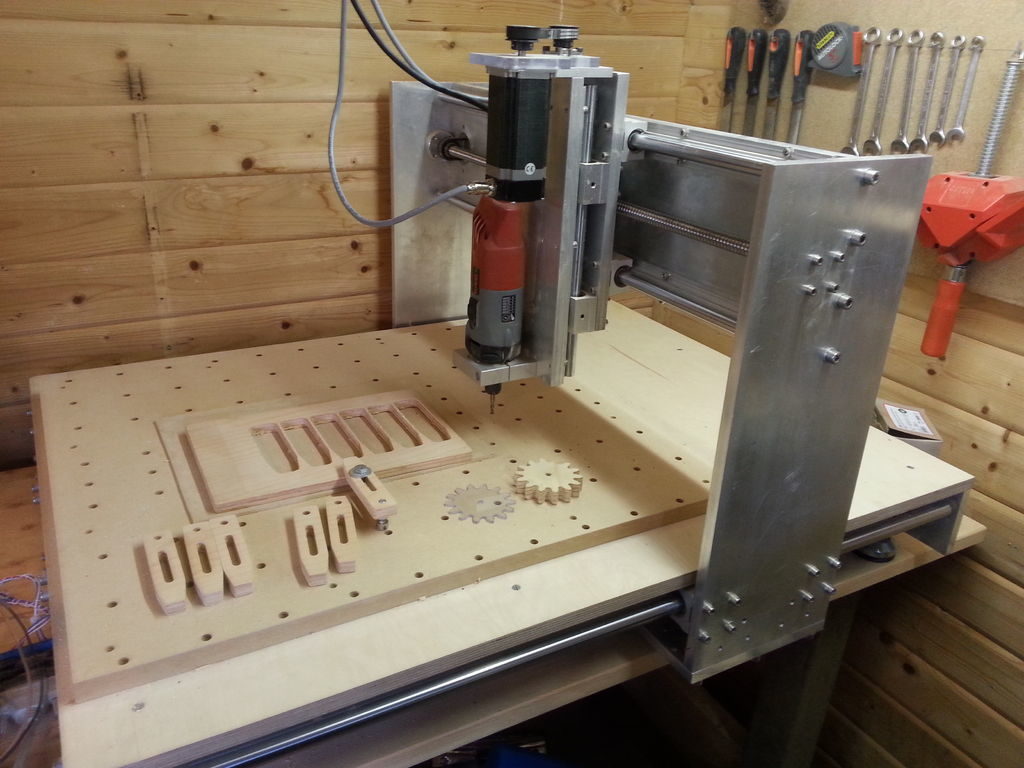

Recently, even smaller laboratories, factories, and machine shops have started using CNC machines for prototypes, parts testing, and small-scale productions. Creating a program is generally time-consuming. However, these programs developed can be adapted or modified for future transactions.

In some instances, a CNC machine is equipped with other techniques in automation such as assembly lines and advanced robotics. Then, it turns the lights-out factory idea into reality.

4. Starting a CNC Career

Individuals who want to start a career as a CNC machine operator do not have to undergo strict or specialized training. They only have to be familiar with various skills and strategies associated with programming and machining. There are many opportunities waiting for skilled CNC programmers as more manufacturers and other businesses embrace this new trend in mass production.

The most ideal way to get familiar with CNC programming is to train. Work with an expert in this field. Many small and large businesses that aim to learn this new career have been through on-the-job training.

On the other hand, CNC programmers will still have to start with the most basic step of learning different things in the field of CNC programming. They should learn how machines and tools work such as milling machines and lathes. This is the easiest way of knowing more about metallography to fully understand how G-Code can be used in various developing custom programs.

Most aspiring CNC programmers even go beyond learning the fundamentals of G-code and other common aspects of using CNC machines. They often delve deeper into learning how to use some programs that are used alongside CNC and G-code. Some of these programs are the CAM (Computer Assisted Machining) programs and the CAD (Computer Assisted Design) programs. CNC programming brings a lot of opportunities for learning and career development.

There are internships and apprenticeships available for any CNC-related occupation. It is recommended to try local factories or machine shops for a start. At present, many small manufacturing businesses and local companies have been discovering more of the techniques in production using CNC programming.

The Value of CNC Programming

As CNC Programming becomes more popular, many opportunities start to come for the programmers. CNC Technology becomes more complex as machine tools become more precise and more capable of techniques. The future of the factories and other businesses will be centered on the use of CNC principles as the new technology grows such as 3D printing. Read more about this on SummitMT.