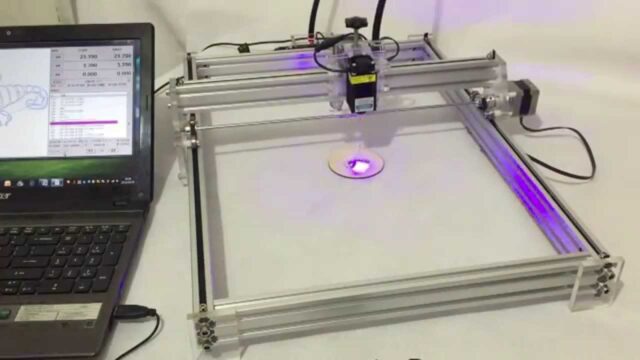

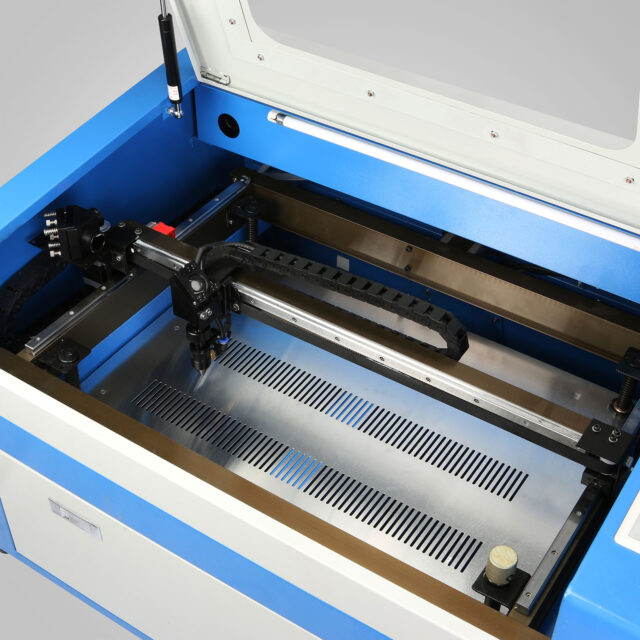

Clean, accurate and precise engraving. That’s what you can expect when you go for a laser engraving machine. Whether you are looking for permanent enduring marking or adding distinction to a product or complying with regulations, engraving could be just the thing you need.

Laser engraving machines aren’t cheap, though, nor are they created equal. Further, they are designed to last, so you will likely be stuck with whatever choice you make for years. That means you have to take your time to find the one that best suits your needs before you commit any money to purchase. Get more on this site to better understand the typical scope and diversity of laser engraving machines.

Laser engraving machines and manufacturers can be evaluated in several ways. Here’s a look at the key factors you should use to compare different machines.

1. Your Budget and the Total Cost of Ownership

No person or organization has unlimited financial resources. Ergo, it’s inevitable that you have a budget that defines how much you can spend on a laser engraving machine. The cost of a machine ranges from several hundred dollars to several thousand. While going for the cheapest machine is certainly not the most prudent thing to do, realistically, you can only buy the laser engraving machine you can afford.

So having a price cut off will prevent you from spending time gauging machines that are outside your limits of affordability. In any case, there isn’t necessarily a direct relationship between price and quality. Buying the most expensive equipment doesn’t guarantee the highest quality. In fact, beyond a certain price point, the differences between the core function of the machines become relatively insignificant.

Nevertheless, make sure you are looking at the total cost of ownership. A laser engraving machine that lasts 10 years may be much cheaper in the long-term compared to a dirt-cheap machine that breaks down after 2 years.

2. The Core Application

You will run into machines that have the capacity to perform laser marking, laser cutting, and laser engraving. While this demonstrates the machine’s versatility, it might not necessarily be of many benefits to you. Be careful not to fall for the marketing campaign of manufacturers touting multi-purpose machines. You could end up paying a premium for functions you’ll hardly ever use.

Remember that just because a machine can do all three functions doesn’t mean it can do all three equally well. There’s often a compromise where one function will be executed excellently while the others will be complementary and, therefore, at a lower performance level. If your core goal is engraving, it’s best that you focus on laser engraving machines only, as they are more likely to perform better while remaining within a reasonable price range.

3. Machine Throughput

Irrespective of the purpose for which the laser engraving machine is intended, throughput is a factor you cannot afford to ignore. Check the number of items the machine can engrave per hour and compare it against the needs of your business.

Don’t just consider your demands of today. Think about your business growth and how that will stretch your engraving requirements in the future. Even if your business or operations are small at the moment, you must make a purchase that will make sense over the short- to medium-term. That way, you don’t have to return to the marketplace soon in search of a higher capacity machine.

Laser engraver throughput can also be a bottleneck in your overall production process. If the engraving machine cannot keep up with production, you’ll be losing out on your potential sales. On the other hand, a high throughput allows you to mass-produce and, therefore, lower your per-unit sales price, accelerate delivery and grow your overall competitiveness.

4. Focus on the Technology and Mechanism as Opposed to the Brand

Blackberry. Nokia. Motorola. Not too long ago, these brands dominated the mobile phone market. Today, they’ve ceded market share immensely to other phone makers, with some like Blackberry struggling to just stay afloat. Often, this demise is the result of an industry leader failing to innovate or not recognizing fast-evolving market trends. A key learning point here is that big brands don’t always develop the best products or the best technology.

As you shop for a laser engraving machine, therefore, don’t be overly enamored with established names while disregarding newer upstarts. While there’s certainly safety and reassurance with going for a brand that’s popular and has many years-experience manufacturing laser engraving machines, keep an open mind. Smaller, newer companies often go over and beyond customer expectations in their quest to compete with their bigger rivals.

Before you buy, extend your gaze to lower-profile brands, so you don’t miss out on great value hiding in plain sight.

5. Check Warranty and Support

Like any other electro-mechanical equipment, laser engraving machines don’t last forever. They will fail at some point. Sometimes, failure will be determined by how hard you push the machine. At other times, it’s a manufacturing defect. In other instances, it’s simply a workplace accident that may have ruined something.

Whatever the reason for an engraving machine’s failure, you need to have the assurance that the warranty and/or support guarantees are good enough to blunt the impact on your finances and operations. When failure occurs, you need the problem fixed quickly so you can get back to work with minimal disruption.

Look at the small print of the product warranty and pay even greater attention to the support resources the manufacturer and supplier make available to customers. If anything is unclear, talk to a support technician or customer service representative from the company. Where possible, send your inquiry via email to maintain some documentary proof of any assurances you are given in case you need to refer to these in the future.

Buying the right laser engraving machine is about choosing a system that can cater to your engraving needs today, but that has adequate capacity to cover your growing demands tomorrow. By weighing laser engraving machines against the above factors, you are more likely to avoid common buyer pitfalls and therefore get the right machine for the job.